History

Company founded by necessity

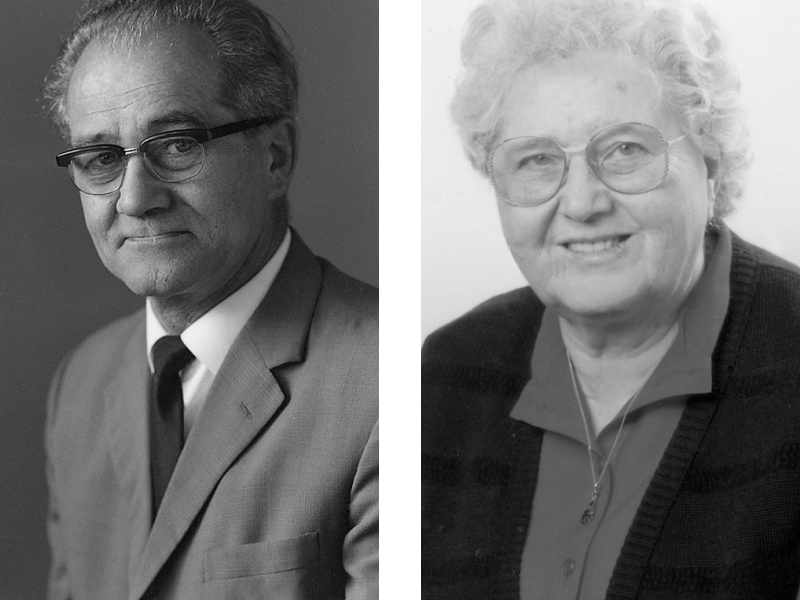

There are “born” entrepreneurs and those that are “made”. Franz and Anna Kammerer rank among those that are “made” – among those that have “made it through” even. They decided to set up their own company out of necessity, rather than ambition. The family were in the same position as millions of other unemployed people.

In 1938, Anna Kammerer registers a manufacturing company under the name of “Fr. A Kammerer Metallwaren – Masseartikel”. In modest premises, they set about manufacturing a range of parts used in watchmaking and precision engineering in Triberg.

As a trained watchmaker, Franz Kammerer knows what the local watch manufacturers need. They face great pressure in the war and postwar years. Even after returning from military service and imprisonment, it is not possible to run an orderly business.

An idea leads to series production

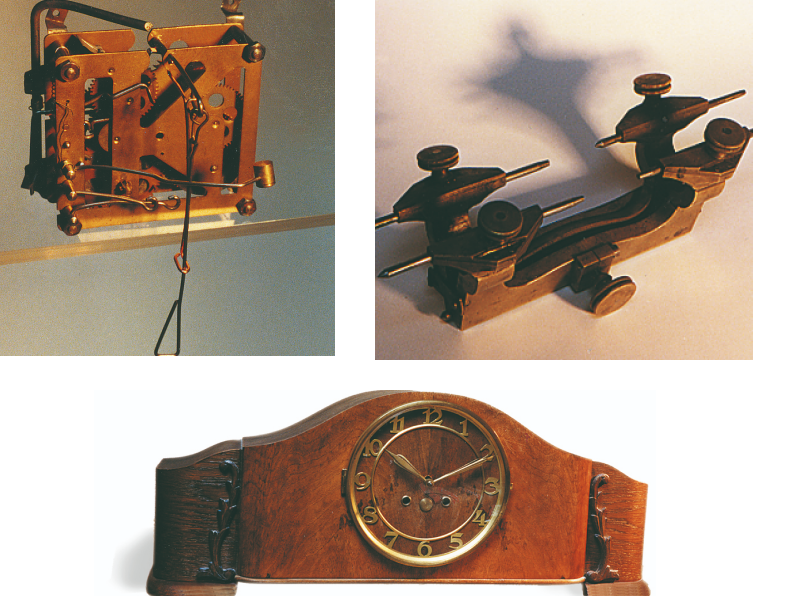

In 1947, Franz Kammerer designs a clock mechanism with a chime which, once wound, would run for 14 days long. This clock mechanism proves to be so good that it finds its way into the production of mantel clocks. With this clock mechanism, it is possible to carry out a modest series production for the first time since the war.

One year later, Franz Kammerer designs the smallest cuckoo clock mechanism to date. It measures just 60 x 65 mm and is also suitable for series production. Thanks to the hard work of Anna Kammerer, they have enough to provide for the large family. But after a few years, the clock mechanism business declines more and more, despite great effort. They have no other option but to look for new production opportunities.

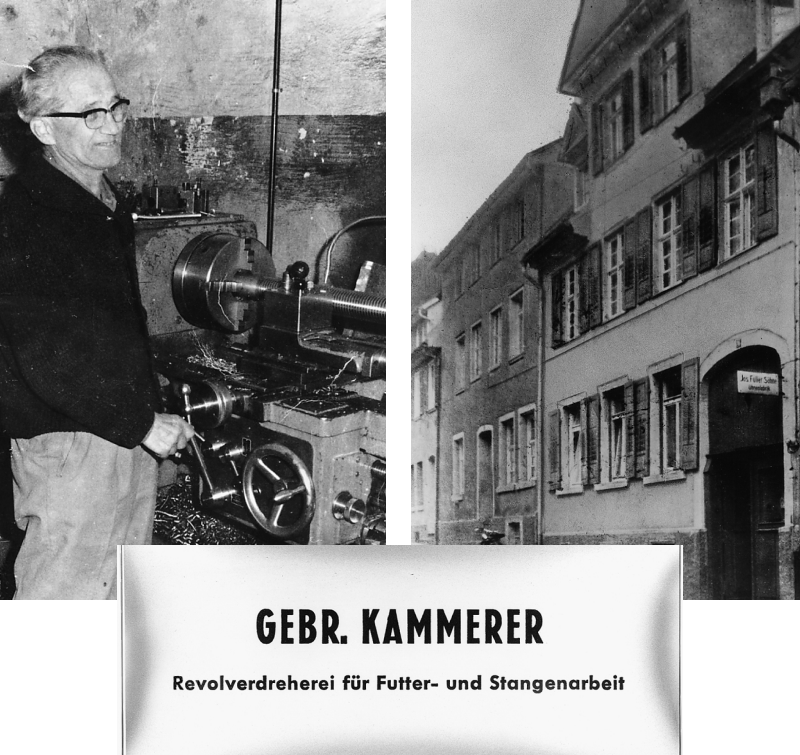

Anna and Franz Kammerer recognise an opportunity to become more independent and flexible by manufacturing turned parts. The customer base is more widely distributed and consists of different industrial sectors. This also provides a more secure base in terms of commercial risk.

Reorientation

The decision to make a fresh start, for what is now the third time since the company was founded, soon proves to be a step in the right direction. The production of turned parts gradually develops into an acceptable source of income. For the first time, the urgently needed profits are made.

Screw production

With the acquisition of a neighbouring building, they are able to create new production space as the original building has now reached its capacity limit. In the same year, the product range is also extended. Threaded parts are now being produced too. This step will set the course for the subsequent development of the company.

Evolution into a specialist company

Thanks to the hard work of Klaus Kammerer, Master Precision Mechanic, and Wolfgang Kammerer, Master Turner, and the motivational force of Anna Kammerer, they manage to markedly increase turnover and their financial success.

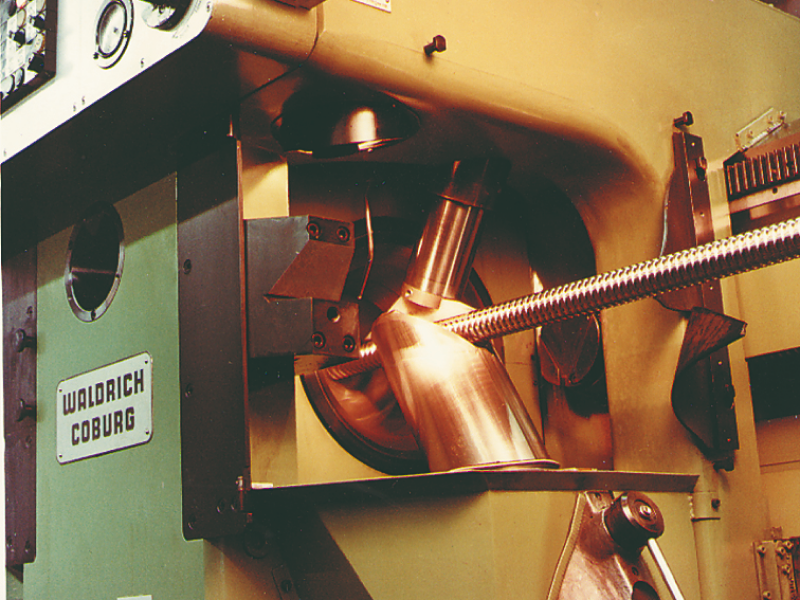

In 1970, part of the workforce is able to move to additional rented premises. They are in a position to make their first major investment – the procurement of a “Waldrich” thread peeling machine.

This machine primarily enables the precision of the screw’s lead to be optimised. It also means considerable time savings. Kammerer evolves into a specialist company for lead screws. In 1971 Kammerer exhibits at the European “EMO” machine tools trade fair for the first time and is thereafter a regular exhibitor at this specialist fair in Hanover.

New company building sets the course

Word gets around among customers about the high level of service. The workload is equally as high. Once again, they reach the limits of their capacity. The purchase of the former Triberg Magistrates’ Court provides a suitable opportunity for expansion. The new business premises has good transport links. A production hall is constructed on the accompanying grounds to meet the ever-growing requirements.

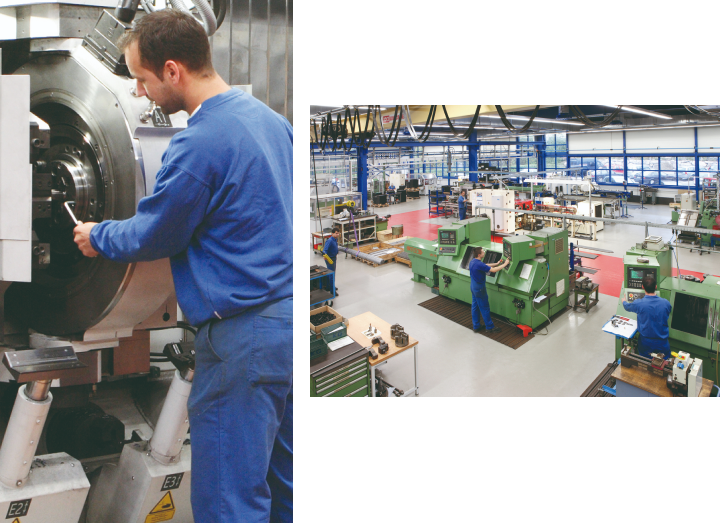

Since 1979, the company has reached a level, in terms of technology and personnel, which enables it to step forward as a training company. All trainees are taken on by the company. This policy is also to apply in future and provide the company with skilled workers. In doing so, Kammerer Gewindetechnik contributes to employment in the region.

Eventful years follow

The newly created capacity is reflected in a further increase in demand. Additional skilled workers are employed. But by 1985, the company needs more space again. The hall has to be expanded. Now with a production area of 1500 m², the machinery is also switched to state-of-the-art electronically-controlled CNC technology. A controllable high-bay warehouse is set up in part of the new hall. With 60 employees, the company is one of the most sought-after specialist manufacturers for trapezoidal screws, worms and worm shafts. Cross roll screws and ball screw drives nationally and internationally.

CNC machines are increasingly used, for contemporary and traditional production

Sons become Managing Directors

The former limited partnership becomes a GmbH in 1986. Brothers Klaus and Wolfgang Kammerer are appointed as Managing Directors.

Looking back at 50 years nur ein Bild

Fuelling progress with EDP, CNC and CAD

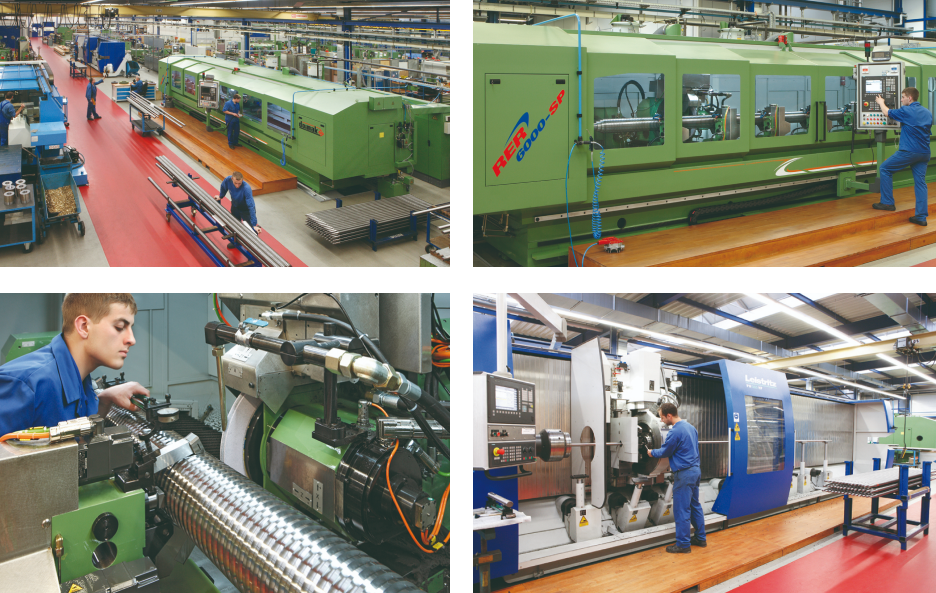

Kammerer Gewindetechnik has also made considerable investments in recent years in order to use state-of-the-art, forward-looking production processes to offer the ultimate in what is currently technologically possible. Customers are companies from the fields of machine tool building and precision engineering. Manufacturers of handling systems and telescopic lifting systems, the aviation industry, medical engineering, measurement technology and reprographic technology. Manufacturers of robots, the automotive industry and several other industry sectors.

New generations bring expansion and innovation

As the sons of Klaus and Wolfgang Kammerer, a young generation of entrepreneurs enter their parent’s business, this accelerates development both commercially and technically. Both express a modern leadership style, with the inclusion of employees in day-to-day operations. At Kammerer Gewindetechnik considerable investments are made, not only in production, but also in the environment and safety. Achim Kammerer, specialist in business administration, responsible for sales and administration brought many advantages to the organisational and business management processes with the comprehensive use of EDP. Following his engineering studies, Peter Kammerer established the Design and Development department. Quality assurance is a long-standing topic. In 1996, Kammerer became DIN ISO 9001-certified.

A further production hall totalling 1300 m² is built in two stages 1994 – 1996. Kammerer sets itself the task of further consolidating its technological lead with the new hall.

Investment in the future + double the production space

Yesterday’s visions become concrete reality ever more quickly these days. To accommodate the continuous development of the company, including in the future, it is necessary to expand the production and administration space to a total of 5500 m². This expansion is not possible at the existing company headquarters. Despite the ties to Triberg, the only solution is to build on the company’s own plot in the Hornberg-Niederwasser business park. The new company building enables considerable improvements to be made in logistics.

It is not just the company’s products that ensure its survival but also its expertise and its ability to adapt to the market and what customers will want tomorrow. Kammerer Gewindetechnik is now optimally equipped and prepared in this regard. Production on a single level optimises processes and increases productivity.

eigert die Produktivität.

A new generation

The company’s contemporary approach at the EMO trade fair in Hanover impresses the sector and customers.

Further expansion

The additional hall offers around 1400 m² of additional production space

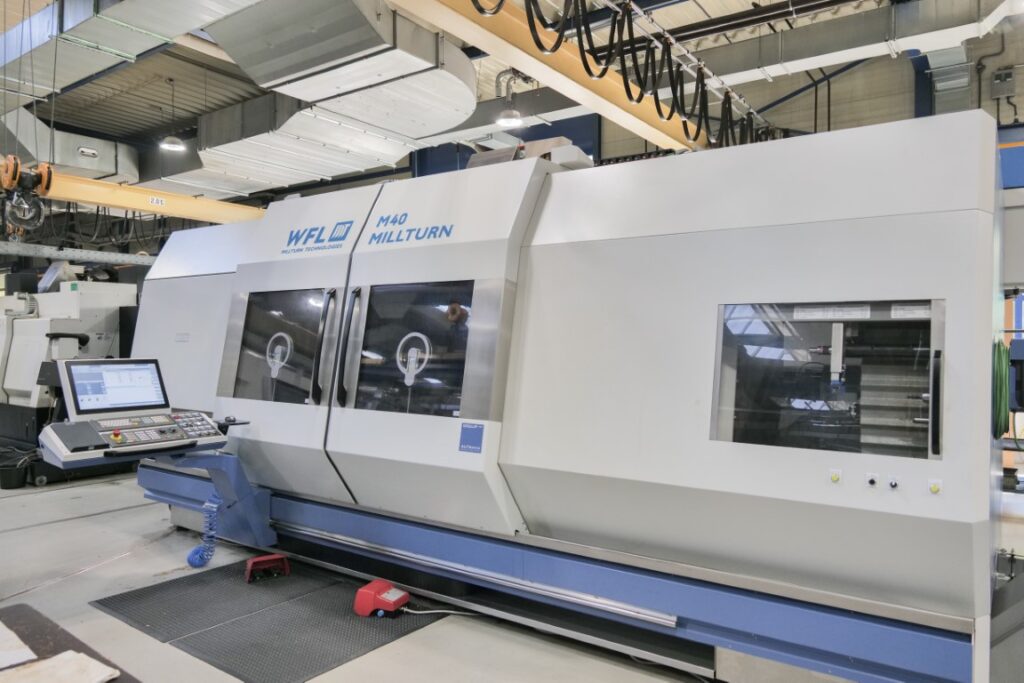

Innovative production technology

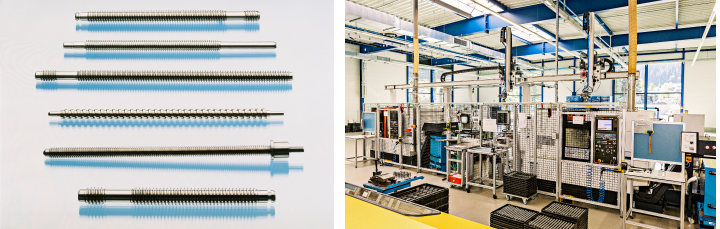

Innovative production technology ensures maximum precision. For example, Kammerer is able to produce screws with a thread length of up to 6 m in a single clamping operation and a diameter of up to 160 mm on the external thread grinding machine and the whirling machine.

Expansion of the automotive department

Kammerer assists with the development of the thread for the new rear-wheel steering at transmission manufacturer ZF Friedrichshafen. Sample parts are produced – the first step towards series production of the new project.

Company anniversary – 75 years of Kammerer

In summer 2013, we are celebrating tradition. Kammerer Gewindetechnik marks its 75th year. And we take the opportunity to raise a glass with customers and business partners, our employees and their families. On June 18th, 2013, we celebrate in the festival hall in Hornberg with everyone who has supported and worked with the company over the course of the last 75 years. We welcome the former Minister President Dr. hc. Erwin Teufel as keynote speaker for our customers and business partners. There is also an in-house celebration for employees and their families on June 29, 2013. We have laid down our 75-year company history in a high-quality book of over 100 pages long.

New hall in Hornberg-Niederwasser

In April 2013, work begins on our new production hall. Almost all parts for the Automotive department are being produced here. The move to the 2000 m² hall takes place in January 2014. Initially six employees work in 2-shift operation in a production space of 1500 m². This becomes 13 employees in three-shift operation – and rising.

All series items are moved to the Automotive plant

Production is switched over to line production

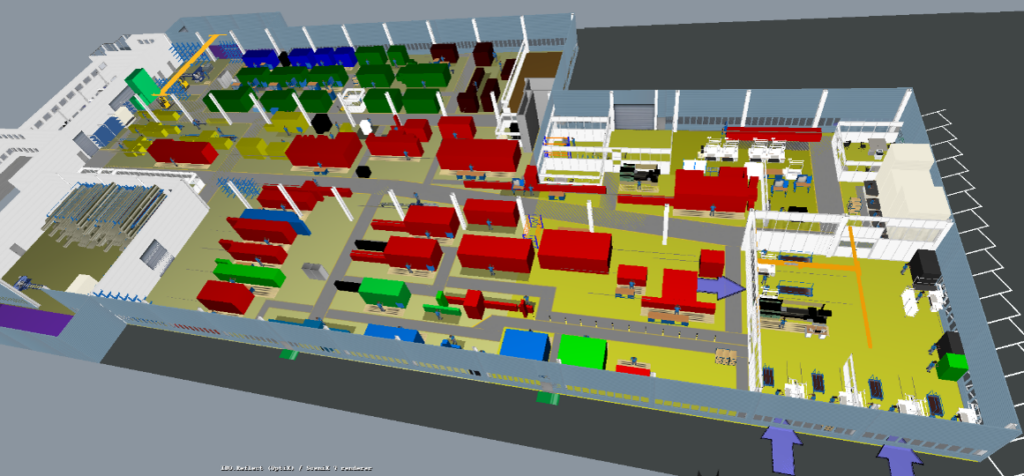

Digitally networked production at Kammerer Gewindetechnik

Thanks to the Value Facturing assistance system used by Kammerer, all the systems and parties involved in the production process are networked.

The software is integrated into Production and Assembly as a web server and directly connected to all available systems.

The control systems for all systems involved in the production process can communicate directly online.

The software has access to real-time data: The machine utilisation can be seen at a glance on a statistics portal.

To get an initial feel for the software, it was used in a small area at Kammerer with six machines to begin with.

The other areas, and the statistics, are to be implemented at a later date.

Investment in production technology

Expansion of the PV system for plant 1 and new PV system for plant 2